Rebecca Morell,scientific editorAnd

Alison Francis,Senior Science Journalist

Tony Jolliffe/BBC News

Tony Jolliffe/BBC NewsIt sounds like science fiction – a factory located hundreds of kilometers above the Earth churns out high-quality materials.

But a Cardiff-based company is one step closer to making it a reality.

Space Forge sent a factory the size of a microwave oven into orbit and demonstrated that its oven could be turned on and reach temperatures of about 1000°C.

They plan to produce semiconductor material that can be used on Earth in electronics, communications infrastructure, computing and transportation.

Tony Jolliffe/BBC News

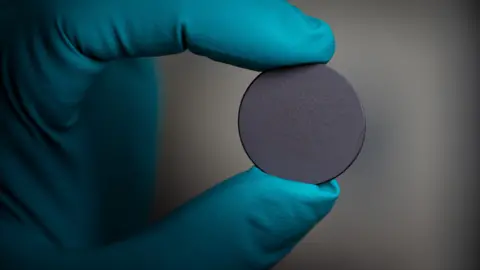

Tony Jolliffe/BBC NewsConditions in space are ideal for creating semiconductors, in which the atoms that make them up are arranged in a highly ordered three-dimensional structure.

When they are produced in zero gravity, these atoms line up absolutely perfectly. The vacuum of space also means that contaminants cannot penetrate inside.

The purer and more ordered the semiconductor, the better it performs.

“The work we're doing now allows us to create semiconductors in space that are 4,000 times purer than we can make here today,” says Josh Western, CEO of Space Forge.

“Semiconductor like this will be used in the 5G tower where you get your cell phone signal, it will be in the car charger you plug your electric car into, it will be in the newest airplanes.”

Tony Jolliffe/BBC News

Tony Jolliffe/BBC NewsThe company's mini-factory launched in the summer on a SpaceX rocket. Since then the team has been testing their systems from mission control in Cardiff.

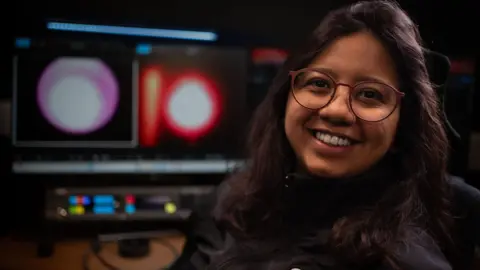

Veronica Viera, the company's head of payload operations, shows us an image that the satellite transmitted from space.

The photo was taken from inside the oven. It shows the bright glow of plasma, a gas heated to about 1000°C.

She said viewing the image was “one of the most exciting moments of my life.”

“This is very important because it is one of the main ingredients we need for our space manufacturing process,” she explains. “So to be able to showcase that is amazing.”

Space Forge

Space ForgeThe team is now planning to build a larger space factory that can produce semiconductor material for 10,000 chips.

They also need to test the technology for delivering the material back to Earth.

The future mission will use a heat shield called Prydwen, named after King Arthur's legendary shield, to protect the spacecraft from the high temperatures it will experience upon re-entering Earth's atmosphere.

Other companies are also looking higher, producing everything from pharmaceuticals to artificial fabrics.

“Manufacturing in space is happening now,” says Libby Jackson, director of space at the Science Museum.

“This is just the beginning, and at the moment they are still showing it in small quantities.

“But having tested the technology, it really opens the door to an economically viable product where things can be produced in space and brought back to Earth and benefit everyone on Earth. And it's really interesting.”