Chris BaraniukTechnology reporter

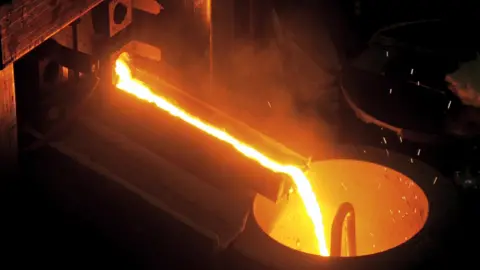

Boston Metal

Boston MetalA kindergarten, a gym, a tax consultant – and a mini-experimental metallurgical plant. These businesses are among those that make up a small commercial and industrial area in Woburn, Massachusetts.

“People abandon their children. This is a prime example of what the future of steel looks like,” says Adam Rauwerdink, vice president of business development at US clean steel startup Boston Metal. “You can make steel and share a parking lot with a daycare center.”

Boston Metal has come up with a way to use electricity to remove oxides and other contaminants from iron ore, a substance that must be mined on Earth before new steel can be made.

The process involves dispensing ore into an electrolyte and then using electricity to heat the mixture to 1600°C. The molten iron is then separated from impurities and can be released.

Traditionally, extracting this critical iron from ores has required blast furnaces powered by fossil fuels. But the metallurgical industry responsible for 11% global emissions – a huge amount equivalent to all private cars and vans in the world – and so the race is now on to find greener ways to produce these important metals.

American companies are perhaps at the forefront. Steel production in the US is already more environmentally friendly than in many countries, thanks to the popularity of electric arc furnaces there. These furnaces use electricity rather than heat from burning fossil fuels, for example to melt scrap steel and recycle it.

In addition, several new startups, such as Boston Metal, say they can go even further and use electricity for the iron production process, an important step in the production of entirely new, or virgin, steel.

However, the Trump administration has taken less than enthusiastic position to renewable energy and decarbonization projects. It remains to be seen whether these new startups will make a big splash in the steel industry anytime soon.

Transition from traditional blast furnaces to electric arc furnaces can reduce carbon dioxide emissions per ton steel produced from 2.32 tons of CO2 to 0.67 tons of CO2.

To produce iron, some plants could use green hydrogen produced using electricity from 100% renewable sources, says Simon Nicholas, lead steel analyst at the Institute for Energy Economics and Financial Analysis.

But converting steel mills to green hydrogen hasn't gone as smoothly as some expected.

In June, Cleveland-Cliffs, a major US steel producer, seemed to retreat from its plans to build a $500m (£375m) hydrogen-fuelled steel plant in Ohio. The BBC has contacted Cleveland-Cliffs for comment.

“We're seeing projects being cancelled, proponents abandoning projects all over the place,” Mr. Nicholas says of green hydrogen initiatives in particular.

Bloomberg via Getty Images

Bloomberg via Getty ImagesAdditionally, there is a limit to how much steel production can rely on electric arc furnaces, as they currently rely heavily on supplies from scrap steel.

The relatively low supply of scrap steel in China compared to demand has slowed the adoption of electric arc furnaces there. according to some analyzes.

These headaches suggest there is a niche for companies developing alternative ways to produce iron and steel. Boston metal is one of them.

“It’s very similar to how we make iron and steel today—it’s much easier to imagine how it would scale.” [as a result]“,” says Paul Kempler, an expert in electrochemistry and electrochemical engineering at the University of Oregon.

However, he notes that there are still challenges in ensuring that such electrolysis systems do not corrode too quickly over time. Boston Metal says it hopes to have its first demonstration-scale steel plant up and running by 2028.

Electra

ElectraIn addition, the American company Electra uses a different approach to the production of highly purified iron from ores. Unlike Boston Metal, the Electra process occurs at relatively low temperatures, around 60-100°C. First, the iron ore is dissolved in an acidic solution, and then an electrical charge causes the iron to collect on the metal plates. This is similar to the process used today to make copper and zinc sheets.

“These plates are automatically removed from the solution and the iron is recovered,” says Sandeep Nijhawan, co-founder and chief executive. A demonstration plant is planned to open next year in Colorado, which will be able to produce 500 tons of iron per year.

Initially, iron produced in this way would cost more than iron produced using traditional methods. But that green premium could disappear if the company can scale enough, says Mr Nijhawan.

Bloomberg via Getty Images

Bloomberg via Getty ImagesMr Nicholas says new technologies like this are encouraging, but one of the challenges they face is getting to market in just a few years as the need to reduce emissions and curb climate change becomes more pressing: “We have little time to solve the carbon problem.”

Companies like Electra and Boston Metal offer a completely different vision for the steel industry, but they won't get very far without further investment—and a market that values what they do.

President Donald Trump's tariffs on U.S. steel imports are supposedly intended to protect the domestic steel industry—yet they risk significantly raising the cost of steel for American customers.

I ask whether Dr. Rauwerdink is happy with this step or not. “We're very pleased to see a strong focus on critical metals,” he says, arguing that the tariffs are “beneficial” for Boston Metal.

Although he acknowledges that the U.S. government's attitude toward renewable electricity, which Boston Metal says it wants to prioritize as an energy source, has changed recently. And globally, keeping the cost of renewable energy low is important for any company hoping to electrify industries previously dominated by fossil fuels.

“The industry certainly has growing pains,” he says.

:quality(85):upscale()/2025/12/10/948/n/49351759/26f290426939e9f661de61.58679937_.jpg?w=150&resize=150,150&ssl=1)