Chris BaraniukTechnology reporter

MVV Energy

MVV EnergyI was told that the pipe that will feed the heat pump drawing water from the Rhine River in Germany is so large that it can be walked completely vertically.

“We plan to consume 10,000 liters per second,” says Felix Hack, project manager at energy company MVV Environment, describing the 2-metre diameter pipes that will suck up river water in Mannheim and then return it after collecting heat from the water.

In October, parent company MVV Energie announced its plan to build what may be the most powerful heat pump modules ever. Two units, each with a capacity of 82.5 megawatts.

This is enough to power about 40,000 homes through a district heating system. MVV Energie plans to build the system on the site of a coal-fired power plant that is transitioning to cleaner technologies.

The scale of heat pumps was partly determined by restrictions on the size of the equipment that could be transported along the streets of Mannheim or perhaps on barges along the Rhine. “We're not sure yet,” Mr. Haque says. “He may come across the river.”

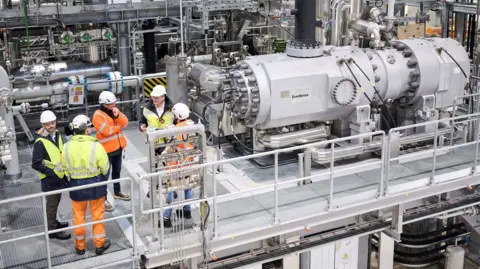

One person with knowledge of the project is Alexandre de Rougemont of Everllence (formerly MAN Energy Solutions), another German company that also makes extremely large heat pumps. “Yes, it’s a competition,” he says. “We're open about it.”

Heat pumps absorb heat from the air, the ground or, in these cases, bodies of water. The refrigerants inside heat pumps evaporate when even slightly heated.

By compressing the refrigerant, you increase this heat even more. The same process occurs in heat pumps designed to supply individual homes, but on a much larger scale it occurs in giant heat pumps that serve entire areas of a city.

As cities around the world strive to decarbonize, many are choosing to purchase large heat pumps that can be connected to district heating networks.

These networks allow hot water or steam to reach multiple buildings connected by many kilometers of pipes. To meet demand, increasingly larger heat pump models are emerging.

“There has been a lot of pressure on us to move our heat production to new sources, especially renewable sources,” explains Mr Hack, discussing the decommissioning of coal-fired units at the Mannheim power station. “The site is right on the banks of the Rhine, already has a strong electrical connection and is connected to the district heating network, so it makes sense to install heat pumps here,” he says.

He notes that this technology is possible in part because of the availability of very powerful compressors in the oil and gas industry, where they are used, for example, to compress fossil fuels for storage or transportation.

MVV Energy

MVV EnergyWork on the Mannheim project is due to begin next year. Heat pumps with a total capacity of 162 MW are due to enter full operation in the winter of 2028-2029. Mr Haque adds that the multi-stage filter system will prevent the heat pumps from sucking fish out of the river, and that modeling suggests the system will affect average river temperatures by less than 0.1°C.

Such installations are not cheap. Installing a heat pump in Mannheim will cost €200 million ($2.3 million; £176 million). Everllence's Mr de Rougemont says his company's heat pump equipment costs around €500,000 per megawatt of installed capacity – this does not include additional costs for buildings, associated infrastructure and so on.

Everlens

EverlensEverllence is currently working on a project in Aalborg, Denmark, which will be even larger than the system in Mannheim, with a total capacity of 176 MW. However, it will use smaller modules – four 44 MW units – and is due to come online in 2027, when it will supply almost a third of the city's heating needs.

These 44 MW machines are actually the same ones used in the previous project, now fully operational, south of Aalborg in Esbjerg. There they do not operate at maximum power, but supply 35 MW each.

Large hot water storage tanks, each holding 200,000 cubic meters of liquid, will give the system additional flexibility, Mr. de Rougemont adds: “When the price of electricity is high, you turn off your heat pump and provide heat only from the storage.”

Veronika Wilk from the Austrian Institute of Technology says: “Heat pumps and district heating systems are a great match.” Such systems can collect heat from bodies of water or even wastewater from treatment plants.

Dr Wilk points out that when you use several large heat pumps in a district heating network, you gain flexibility and efficiency. You can run two of the four heat pumps in the fall, say, when less heat is needed than in the dead of winter.

Getty Images

Getty ImagesAll of the systems mentioned so far harvest energy from water sources, but less commonly very large heat pumps can also use air as a heat source. Even in a relatively cold city like Helsinki.

“The sea in front of Helsinki is too shallow,” explains Timo Aaltonen, senior vice president for heating and cooling at energy company Helen Oy. “We calculated that we would need to build a tunnel over 20 km long to the ocean to get enough water. [with a] the temperature is quite high.”

Helsinki is in the process of radically revamping its district heating system. The city has added heat pumps, biomass burners and electric boilers to a 1,400 km network that connects almost 90% of the Finnish capital's buildings, Mr Aaltonen adds.

Heat pumps convert one kilowatt-hour of electricity into several kilowatt-hours of heat, but electric boilers cannot do this and are therefore considered less efficient.

I ask why Helen Oy decided to install these hundreds of megawatts of boilers, and Mr Aaltonen responds that they are cheaper to install than heat pumps, and having them also means he and his colleagues won't have to rely entirely on air, which is limited in terms of the amount of heat it can provide at scale. In addition, electric boilers can help absorb excess renewable energy and provide a grid balancing function, he says.

There are no heat pumps in the UK that can compete with the systems being developed in Denmark, Germany and Finland. However, some new district heating networks are already on the way, such as the Exeter Energy Network, which will supply electricity to the University of Exeter and other consumers.

The minimum planned network capacity is 12 MW. It will be equipped with three 4 MW air-to-water heat pumps, with the first unit due to become operational in 2028.

Keith Baker from Glasgow Caledonian University, who researches district heating systems, says there is scope for further use of the technology in the UK. Water in abandoned mines, maintaining a relatively stable temperature, begins to supply here, for example, larger heat pumps.

Post-industrial and rural areas, where there is enough space to install heat pumps and thermal storage tanks, are “the best places,” he says.