The Atacama desert in Chile is one of the most beautiful and forbidding places on Earth, so dry that it’s sometimes used by scientists to test run Mars missions. Most years the area sees less than half a centimeter of rain, but this past September unusually heavy precipitation brought forth a desert bloom, blanketing the ground with delicate purple flowers that disappeared as quickly as they’d appeared.

It was a rare treat for locals used to grimmer ornamentation: Since 2001, colorful mountains of used clothing have been the main feature growing across the Atacama. By the time the largest mound was set on fire in 2022, it contained some 100,000 tons of discarded fabric, roughly the weight of an aircraft carrier. Today, piles like it continue to grow.

Secure · Tax deductible · Takes 45 Seconds

Secure · Tax deductible · Takes 45 Seconds

This fashion graveyard has become so large that some outlets have dubbed it the “great fashion garbage patch.” It owes its growth to the nearby duty-free port of Iquique, where Chile imports all manner of international goods without customs or taxes — including heaps of used clothing from the United States, Europe, and Asia. While the best items are resold to international markets, overwhelming volumes of cheap fast-fashion pieces don’t make the cut. Instead, they are dumped in the desert — an open secret that the government largely ignores. The burnings, whether they’re intended to destroy the evidence or make more space, fill nearby towns with smoky, unhealthy air.

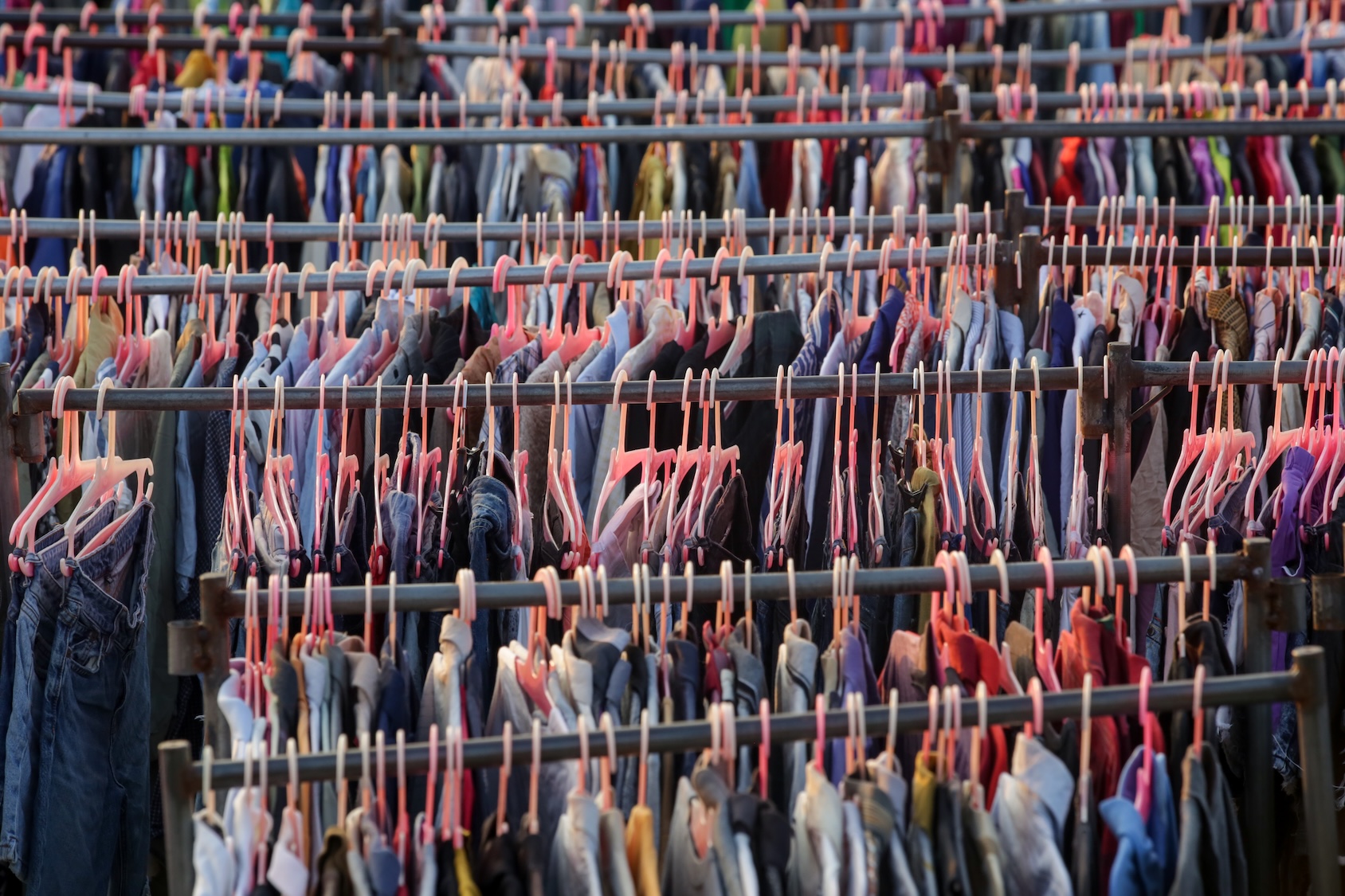

Martin Bernetti / AFP via Getty Images

Activists have been fighting against this desert dumping for years, documenting the burnings and suing both the federal and local governments to stop it. But the real blame for Chile’s mess lies beyond the country’s borders. From the moment these garments are spun from fibers to the time of their undignified disposal, they are part of a vast global pollution machine — one that has grown massively as the world economy has globalized and factories have begun pumping out ever-cheaper, ever-faster styles to customers half a world away.

This new hyper-vast, hyper-fast-fashion system is phenomenally destructive. Today, the clothing trade generates some 170 billion garments a year — roughly half of which wind up being thrown out within that year, and almost all of which despoil the world’s land, air, and seas. In the process, it generates as much as 10 percent of all planet-warming emissions, making it the second-largest industrial polluter, while also holding the distinction of being the world’s second-largest consumer and polluter of water. When all its many offenses are cataloged and counted, fashion is the third-most-polluting industry on the planet, after energy and food.

Things weren’t always this bad. While fashion has long left trails of environmental devastation in its wake — just ask the poor snowy egret, sacrificed by the thousands to decorate a generation of women’s hats — it was kept in relative check, even as globalization ramped up, by a 1974 trade agreement known as the Multi Fibre Arrangement. This agreement allowed nations to regulate the number of textile and clothing imports allowed into their countries, thereby protecting domestic production. But its expiration on January 1, 2005, essentially heralded fashion’s NAFTA moment. Low-cost goods from countries such as China and Bangladesh began flooding the United States and the European Union, which undercut domestic production in developing countries by saturating those markets with used clothing. The loosening of the century-old de minimis loophole in 2016, which allowed packages under $800 to enter the United States without tariffs, allowed Shein and Temu, the notorious Chinese e-commerce giants, to grow exponentially.

Some observers of the fashion industry have speculated that it might be on the cusp of a reckoning. The elimination of the de minimis exemption, together with Trump’s “Liberation Day” tariffs, has sent shock waves through the industry, rattling U.S. consumers — and with them, major brands like Shein and Temu. Both have already begun to compensate for the drop in U.S. sales by redirecting their efforts toward Europe and Australia while moving their operations to other countries. Other companies, meanwhile, have simply begun offsetting their losses by trimming their sustainability efforts, raising serious fears of an even faster race to the bottom.

All of which raises the questions: How did we get into this situation? And, more important, how do we get out?

Olga Pankova / Getty Images

Step 1: A dirty, bloated underbelly

To understand how our garments got so noxious, it helps to go back to the beginning: to how our clothes become clothes in the first place. Take any item of attire — from Lululemon athleisure leggings to the summer of 2024’s viral Uniqlo baby tee; from the swankiest gowns to the most nondescript knockoff jeans — and the story is almost always the same: Most clothes start their lives deep in the ground, either as seeds of cotton or in the nearly 342 million barrels of crude oil that go into the making of synthetic fabrics every year. Most of the problems start with one of these two origin stories.

Today, synthetic fibers make up nearly 70 percent of all textile production. Polyester has become particularly ubiquitous across styles and brands, whether those brands are fast-fashion behemoths or rarefied luxury houses. Its soft, stretchy nature can mimic traditional textiles or be engineered into modern, high-performance meshes. Its low cost — just half the price of cotton in some instances — makes it an attractive option for brands and suppliers looking to snag profits while offering lower prices to customers.

But beneath its malleable folds lies a nasty business. Commercialized by the chemical giant DuPont in the mid-1900s, the process of making polyester involves superheating two petroleum-based chemicals — ethylene glycol (also used in antifreeze) and terephthalic acid (commonly used in plastic bottles) — and extruding the mixture through tiny holes to form yarn. In 2015, this process was estimated to produce as much annual carbon pollution as 180 coal-fired power plants. As the resulting polyfabrics are woven, washed, treated, and sewn into garments, they continually shed plastic microfibers.

Meanwhile, plant-based fibers like linen and cotton, which currently make up a quarter of global textile production, come with their own complications. Compared to other major crops, cotton is considered resource-intensive, earning a reputation among environmental organizations, such as the World Wildlife Fund and the Environmental Justice Foundation, as particularly thirsty, based on the amount of water it consumes, and dirty, based on the quantity of chemical pesticides used to grow it. The cotton fiber needed to manufacture a classic jeans-and-tee outfit requires roughly 500 gallons of irrigation water (and an additional 1,500 gallons of rainwater) to grow. And while cotton takes up a little less than 3 percent of all farmable land, its production accounts for some 5 percent of all pesticide sales and 10 percent of insecticide sales.

Other, less common fashion fabrics, such as viscose (made from the pulp of more than 100 million trees per year), come with their own environmental trade-offs — a 2023 report found that nearly a third of those trees came from old-growth or endangered forests. Over the past decade, blended fabrics that mix various types of synthetic fibers and organic ones have become increasingly common, creating an engineering headache for recycling initiatives and spreading plastic’s presence ever further.

The environmental impact of your jacket

Quilted jackets stuffed with down — generally goose feathers — have been standard-issue for the last century. But polyester fill has begun to dominate the market, and manufacturers have relied on a toxic group of chemicals known as PFAS to waterproof the jackets. These “forever chemicals” don’t degrade naturally, and they have infiltrated drinking water, farmland, and the human body. Down carries its own baggage: It often involves plucking feathers from birds while they’re still alive.

Brands have begun developing alternatives to PFAS in anticipation of bans that went into effect in 2025 in California and New York. Patagonia and Vaude have phased out PFAS use entirely, while Gore-Tex, Fjällräven, and Sympatex all offer PFAS-free options.

Patagonia, Houdini, and Cotopaxi have also revamped their process for making synthetic fill to use recycled and plant-based materials and produce less emissions.

The environmental impact of your T-shirt

Growing, weaving, dyeing, and manufacturing cotton into a T-shirt can require more than 700 gallons of water — enough for a single person to drink for 900 days. Cotton cultivation also requires heavy chemical use; some estimates indicate the crop accounts for roughly 16 percent of all insecticides sold worldwide.

Hemp-jersey blends can significantly reduce the carbon footprint of a T-shirt. Hemp has low water needs, requiring as much as 90 percent less water than cotton. And because the plant sequesters a lot of CO2 as it grows, its overall carbon footprint is significantly lower than that of other fibers.

Step 2: Toxic textiles

Once the requisite materials have been grown, harvested, or extracted from DuPont’s primordial ooze, they’re turned into fabric, bleached, and dyed. This is an enormously toxic process that’s estimated to be responsible for 20 percent of water pollution worldwide. Pesticides used to grow cotton are flushed into waterways, along with bleach and the heavy metals — such as cadmium, chromium, lead, and arsenic — found in dye. The World Bank has identified at least 72 toxic chemicals involved in the standard industrial dyeing process, and once those chemicals make their way into aquifers, the knock-on effects are dire.

Dark sludge from clothing factories fills nearby lakes and streams, blocking the light needed for photosynthesis and destroying aquatic ecosystems. Even rinsing synthetic fabrics sends microplastics racing down the drain, and experts estimate that about half a million metric tons of microplastics make their way into the oceans each year — equivalent to the weight of 50 Eiffel Towers. Some of this contaminated water is then reused to irrigate local crops, causing health problems for the surrounding community, reducing crop yields, and harming biodiversity.

The Citarum River, in West Java, Indonesia, is a toxic testament to this process — the transformation of raw fabric into the pretty hues and bright patterns that make our wardrobes pop. Once a pristine waterway that flowed past cozy farming villages and bustling cities, it became a dumping site for hundreds of textile mills in the 1980s. As more and more arose along its banks, they spilled their waste directly into the river and its tributaries, staining them blue, red, yellow, and black and saturating them with mercury, lead, chromium, and other chemicals. For years, people who live near the river have reported skin rashes and intestinal problems along with more serious conditions like renal failure and tumors — and while the Indonesian government vowed in 2018 to make the river’s waters clean enough to drink by 2025, that deadline has come and almost gone. The river remains one of the most polluted in the world.

Jose A. Bernat Bacete / Getty Images

Step 3: How fast is too fast?

Once the clothes have been manufactured and are ready to be shipped, fashion can generally be sorted into several buckets: fast, faster, and ultra-fast. More traditional brands like Levi’s, Gap, and Nike will design a collection of apparel in advance of a season and then commission the production of their garments to factories in other countries, thus starting the clothing’s journey along a lengthy supply chain. According to McKinsey, the lag time between design and sale can be as little as 12 weeks. Fast-fashion brands like Zara, H&M, and Forever 21 move through “microseasons” still more quickly, releasing dozens of collections per year. And ultra-fast-fashion brands like Shein, Temu, and Cider can design, manufacture, and ship a new garment in a matter of days.

All this speed means different kinds of waste, depending on which bucket a garment falls into. To know exactly how much of each garment to make, traditional and fast-fashion retailers try to predict demand. But because each individual blouse, skirt, and jacket requires its own bespoke assembly line, factories incentivize retailers to buy in bulk, which lowers the brand’s cost per item and helps the supplier stay efficient. It’s a tricky balance, but with profits and savings in mind, the default is to order too much.

If you’re curious about which brands might be overstocking offenders, keep an eye out for frequent sales or steep discounts. In 2022, the apparel giant Asos was left with over $1 billion of unsold stock after sales dropped from the previous year. It struck a deal with a resale company to sell its remaining stock at a heavy discount. In the same year, Gap Inc. — which owns brands including Gap, Old Navy, Banana Republic, and Athleta — went on a discounting marathon, with multiple sales events in a row to trim down its warehouse bloat. Luxury fashion brands, which are known for destroying their excess merchandise to maintain their products’ exclusivity and value, are also responsible for the largest Black Friday discounts, with up to 46 percent of stock marked down in previous years.

Available statistics suggest that this global surplus could amount to anywhere between 8 billion and 60 billion garments a year, as reported in The Guardian. And that’s not including the textiles that never get turned into clothing. The destiny of all that material varies: Some of it is sold at a discount or recycled, but much of it winds up in landfills or incinerated.

D3_plus D.Naruse @ Japan / Getty Images

Paradoxically, the new ultra-fast-fashion models embraced by brands like Shein are “more efficient,” according to Valérie Moatti, a former professor of fashion supply-chain management and strategy. Shein, for instance, claims to make only 100 to 200 copies of each garment, with unsold inventory in the single digits — thanks, largely, to its data-forward business model, which leverages predictive AI algorithms to identify “microtrends” in fashion. Yet that efficiency creates its own problems. In 2023, Shein nudged out Zara for the title of biggest polluter in fast fashion.

Shein’s e-commerce model, while speedy, relies on small-package air shipment, which is highly carbon-intensive, instead of the bulk ocean shipping typically used by fashion brands. With up to 10,000 new items released for sale on its site every day, Shein has flooded the U.S. postal system with as many as 900,000 packages a day. This air shipping accounts for up to 38 percent of Shein’s emissions, which nearly doubled between 2022 and 2023 to 16 million metric tons of CO2. By contrast, Inditex, which owns Zara and uses primarily sea and road shipping, reported that it released a little over 2 million metric tons of CO2 transporting its products in the same year.

The environmental impact of your jeans

New denim jeans, traditionally made mostly of cotton, carry many of the same environmental burdens as a cotton T-shirt. In recent years, elastic textures made from synthetic blends have added microplastics to the denim equation.

Washing a single pair of jeans can release up to 56,000 microfibers into wastewater systems. They spread from there into the environment.

Buying secondhand jeans can cut carbon costs by 90 percent, while cold-washing and and line-drying may reduce the carbon cost by 70 percent compared with machine-washing. Extending the lifespan of your garments by just nine months can reduce their carbon, water, and waste footprints by 20 percent.

The environmental impact of your leggings

Most exercise leggings are synthetic, generally made up of roughly 85 percent polyester and 15 percent Lycra (commonly known as spandex). This means they’re a fossil fuel product and will shed microplastics when washed or worn.

Since 2019, the production of activewear made from recycled polyester has increased by 80 percent. Buying from brands like Puma, Patagonia, and Adidas that use recycled polyester may help curb the carbon cost of your outfit. To prevent your clothes from shedding microfibers, the company Guppyfriend offers an eco-friendly washing bag.

Step 4: From closet to landfill

Once the spoils of someone’s latest shopping spree have found a home in their closet, they likely won’t remain there for long. In 2024, researchers found that the average fast-fashion pair of jeans is worn only seven times, giving them a carbon footprint 11 times higher per wear than traditional denim pants. A typical pair of jeans is kept, on average, for four years before being tossed.

Even when clothes are donated, they often end up burned or in a landfill, where they belch greenhouse gases, like methane, as they decay. Anything made with synthetic fibers, like stretchy “denim,” see-through mesh, and athletic wear, sheds plastic microfibers into soil and waterways. And while California and New York have banned the toxic forever chemicals known as PFAS in apparel and textiles, decades of their use in waterproofing outdoor wear means that our discarded rain jackets are leaching the pollutants too.

“In the United States, we consume the most apparel in the world, and so we are also the largest exporters and waste creators of fashion,” said Rachel Kibbe, who leads American Circular Textiles, a coalition that lobbies for fashion policies that are “sustainable, profitable, and resilient” in the U.S. “It’s a missed opportunity to recapture resources that we’ve already put a lot of time, labor, energy, water, and chemicals into.”

Kibbe’s organization is at the forefront of the emerging movement around “circularity,” a term that refers to a closed-loop supply chain that continually repurposes clothing. Touted by international nonprofits, major brands, and advocates alike, the word has become the de facto slogan for those promoting clothing recycling. For Kibbe, circularity means extending the life of the materials as long as possible.

Last year, her coalition provided technical feedback on a California bill that requires manufacturers to manage the recycling and reuse of their textiles. The law, passed in September 2024, mirrors a flurry of similar fast-fashion waste regulations in the European Union. But turning old rags into new garments poses a steep technical challenge. While features like zippers and buttons create their own difficulties for recycling clothes into new fabrics, the bigger issue is the industry’s growing reliance on blended fabrics — an intricate mix of synthetic and natural fibers that are difficult to pull back apart.

Although the technology exists to separate these fibers for reuse, it remains in its early stages and is costly to scale. In 2024, Renewcell, a textile-recycling company that partnered with major brands like H&M and Levi’s, went bankrupt.

The environmental impact of your leather boots

The leather used in shoes and handbags depends on cattle ranching, which is the primary driver of deforestation in the Amazon. Many vegan-leather options consist of synthesized plastics, which come with a heavy chemical burden.

Soles are often made of synthetic rubber, a fossil fuel product that produces three to six tons of CO2 per ton of polymer material. Meanwhile, natural rubber has caused the deforestation of more than 4 million hectares of tropical forests over the past three decades.

There’s a limited number of sustainability-minded shoe brands. Experts say that the most sustainable option for buying leather are stores that use local small-scale suppliers or source the hide as a byproduct from fair-trade farmers. In the future, other alternatives may be made from fungi. In 2023, the biotech start up MycoWorks announced the successful production of the world’s first commercial-scale mycelium biomaterial, which has 80 percent lower emissions than cow leather.

The environmental impact of your running shoes

A single running shoe contains as many as 65 discrete parts that require 360 processing steps to assemble, which is often done using coal-powered machines. On average, making a pair of shoes emits the equivalent of 30 pounds of carbon dioxide, over two-thirds of which come from the manufacturing process.

Companies like Allbirds are producing new types of biofoam materials made from sugarcane and a bioplastic made with methane waste. In 2023, Allbirds introduced its MO.Onshot sneaker, a “net-zero carbon shoe.” Other companies, like Saye, are also using alternative biomaterials, such as plant-based leathers made from cactus, corn, and bamboo yarn.

The circularity movement isn’t an isolated phenomenon. As the outrage over fashion’s many environmental faux pas has grown, so have the efforts to force the industry to mend its ways — through protests, the rise of a robust secondhand clothing market, and textile recycling regulations in the European Union and California. And the industry, ever image-conscious, has started to listen. Many historic offenders like Shein, H&M, and Burberry have set voluntary sustainability goals, including using recycled fabrics, reducing freshwater use, limiting packaging, and cutting emissions.

But these efforts have often been slow and stuttering — more greenwashing than greening. And even at their most rigorous, they have come up against a problem that goes to the very heart of the modern fashion industry: speed. At the same time that brands have begun ramping up their sustainability efforts, many have also begun speeding up their production cycle, churning out ever more clothes at ever faster rates. The result is a fundamental incongruity: an industry hurtling forward at breakneck speed, even as it tries to change course. Or as Kristy Caylor, who has founded several sustainable apparel brands, including the clothing-recycling startup Trashie, observed: “We all know people who are doing a much better job, but overall, we’re still in the speedy cycle. If we’re still consuming at a rapid rate and the materials are better, but we’re still throwing it all out, have we really done a better job?”

Lynda Grose, a designer and professor of design and critical studies at California College for the Arts, agrees that it’s too easy right now to produce new clothes. Even ethical fashion brands produce a great deal of waste. “I would say that the entire industry adopts fast-fashion tactics,” Grose said. “I don’t want fast fashion to be used as a scapegoat — the whole industry needs a magnifying glass.”

Triocean / Getty Images

The industry, which remains largely unregulated, also can’t really be trusted to police itself. To slow the warp-speed pace of modern fashion requires more than ad hoc efforts by individual brands. Tariffs, waste quotas, and taxes on waste could all cut down on the fashion industry’s seemingly intractable garbage issues. And a handful of places are already trying. In 2024, the European Union introduced rules banning large companies from destroying unsold textiles and footwear, while France recently approved legislation that imposes a mix of taxes, advertising bans, and sustainability standards on fast-fashion giants. And while some brands might bristle, many of these efforts — such as incentivizing clothing repair and recycling — could benefit the companies as well as the consumer.

For Lilah Horwitz, the director of content and marketing at Eileen Fisher Renew, which saves and repurposes old Eileen Fisher clothing, sustainability is about taking responsibility for the full life cycle of the clothes, even after they pass into the consumer’s hands. “We will take them back, no matter the condition, and we’re going to spend years trying to figure out what is the best thing to do with them,” she said. The catch is that “you have to make a good product the first time. You make something that hopefully lasts, and then you build the infrastructure and the systems to keep it lasting.”