Zoe CorbinTechnology Reporter, San Francisco

374Water

374Water“There's a lot of disruption that needs to happen,” says Parker Bove of research and consulting firm Cleantech Group.

He's referring to PFAS (perfluoroalkyl and polyfluoroalkyl substances), also known as “forever chemicals.”

These man-made chemicals can be found in items such as waterproof clothing, non-stick pans, lipstick and food packaging.

They are used for their oil- and water-repellent properties, but they do not break down quickly and are associated with health problems such as a higher risk of certain cancers and reproductive problems.

The unusually strong carbon-fluorine bonds they contain give them the ability to persist in nature for decades or even centuries.

PFAS can be detected and removed from water and soil and then concentrated into smaller volumes of high-level waste.

But what to do with this waste?

Currently, concentrated PFAS waste is either placed in long-term storage, which is expensive, incinerated (often incompletely, resulting in toxic emissions), or sent to hazardous waste landfills.

But now cleantech companies are bringing technologies to market that could destroy them.

They are being tested in small pilot projects with potential customers, including some industrial manufacturers, municipal wastewater treatment plants and even the US military.

There is a “large and growing” market for companies dedicated to eliminating PFAS, Mr. Beauvais said.

While it's currently mostly concentrated in the U.S., others are gradually dropping, he said.

In the UK, funding for water companies to investigate PFAS disposal has been provided by water regulator Ofwat in conjunction with Severn Trent Water. project management Explore potential technologies and suppliers.

One of the factors driving the market in the US is legal risk. Thousands of PFAS-related pollution and harm lawsuits have been filed against some of the major chemical manufacturers, notably 3M, which has already paid out billions of dollars in class action lawsuits.

Regulation is also starting to tighten around the world.

Legislative limits on two PFAS in drinking water are now scheduled to take effect in the United States in 2031.

PFAS remains a bipartisan issue, Mr. Bove says, and many expect future U.S. regulation to expand beyond drinking water to include industrial discharges and other sources.

The EU also has legal limits on PFAS in drinking water, which member states must begin enforcing next year.

Aksin Water Technologies

Aksin Water TechnologiesThere are many technologies for destroying PFAS, each with its own advantages and limitations.

One technology that is almost commercially ready is electrochemical oxidation (EC) technology, according to Mr. Beauvais.

Electrodes are placed in water contaminated with PFAS and a current is passed through them, causing the chemicals to break down.

Although energy-intensive, it does not require high temperature or pressure, is easy to operate and integrates into existing treatment systems to concentrate PFAS, says Mark Ralph, CEO of Canadian startup Axine Water Technologies.

Last year, after a successful pilot, it sold its first commercial operation to a Michigan-based auto components manufacturer. It is now up and running, and the customer plans to purchase additional systems for other sites.

374Water

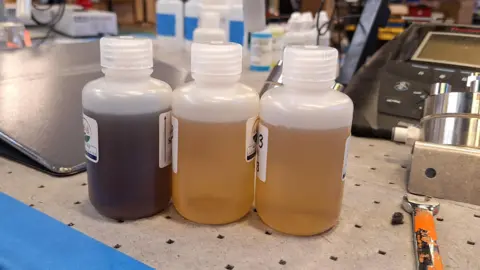

374WaterAnother technology that is keeping pace is supercritical water oxidation (SCWO).

It is based on heating and increasing the pressure of water to such an extent that it enters a new state of matter: the so-called supercritical state. When a PFAS waste stream is introduced, it breaks the carbon-fluorine bonds.

One advantage is that it can process both solid and liquid PFAS waste, says Chris Gannon, CEO of North Carolina-based 374Water.

He says his technology could even destroy PFAS in plastics if they are shredded.

It can be expensive to purchase and maintain—the process is so intensive that it requires a complex reactor and regular cleaning. But it may be more cost-effective if the PFAS is first concentrated before it enters the process.

The city of Orlando, Florida is currently testing 374Water technology at its largest wastewater treatment plant.

City officials are trying to get ahead of the curve, explains Alan Oyler, public works special projects manager.

Levels of PFAS in sewage sludge are not currently regulated, but he expects they will be in the future.

So far, Mr. Oiler is pleased with the destructive power he's seen, but he's also waiting to see how reliable the system is.

The scale of 374Water's current technology is small: it can only process a fraction of the tons of wet sludge the plant produces daily.

But the company is in the process of expanding, and Mr. Oiler expects that within a few years it will be able to process all of the site's materials “ready for when regulations require it.”

Other technologies on the path to commercial readiness include hydrothermal alkaline treatment (HALT), which uses high temperature, high pressure and alkaline chemicals to break down PFAS; and plasma technology, which involves creating an ionized gas (called plasma) to attack and destroy PFAS molecules.

Aquagga

AquaggaHowever, according to Jay Migoda, a professor of civil and environmental engineering at the New Jersey Institute of Technology, there is one potential problem with emerging technologies now: the nasty byproducts of PFAS degradation.

For example, in the case of EO, highly corrosive hydrogen fluoride vapors. Everyone needs a “full study” that takes into account all their contributions and results, he said.

The companies said they either did not produce PFAS degradation products or did not handle them properly.

One important partner of many PFAS destruction companies in testing their technologies in the real world has been the U.S. Department of Defense (DOD).

PFAS contamination at U.S. military installations is a large, under-the-radar problem. This is due, in part, to the use of older firefighting foam formulations used, for example, during training or emergency situations, as well as other methods such as cleaning military equipment.

More than 700 sites are known or suspected to be contaminated, posing a threat to surrounding communities. A judge recently allowed lawsuits against the military alleging PFAS contamination and harm.

Cleanup efforts are where disposal companies could help, and projects have been or are underway at various sites to evaluate the performance and cost-effectiveness of many of their solutions.

One startup, Aquagga, which specializes in HALT technology, recently completed a demonstration project for the U.S. Department of Defense that involved destroying a mixture of firefighting foam among other concentrated liquids containing PFAS.

Huge volumes of foam are currently stockpiled in a variety of places, not just military installations.

Like others, Aquagga sees big opportunities in the next few years to both eliminate foam and address the environmental damage associated with its use.

And beyond the military, an attractive new PFAS waste stream looms on the horizon. The US is actively expanding domestic production of computer chips, a process that uses PFAS in huge quantities. “We can disrupt this,” says 374Water's Mr. Gannon.